In today’s competitive market, the fabric you choose for your bags can make or break your brand’s reputation. Consumers are increasingly seeking out products that offer both durability and style, especially when it comes to backpacks and outdoor gear. This growing demand has made the selection of high-performance materials more critical than ever. Among the standout choices for manufacturers is a specialized composite fabric—0.75 thickness, 290T twill weave, and engineered for superior waterproofing. Let’s explore why this fabric is becoming the go-to option for brands aiming to deliver quality, longevity, and sustainability.

Why Choosing the Right Fabric Defines Brand Success

Modern consumers are more informed and discerning than ever before. They seek products that not only look good but also stand the test of time—especially when it comes to everyday essentials like backpacks and travel bags. Durable, functional materials are no longer a luxury but an expectation. Brands that invest in premium fabrics are better positioned to build trust and loyalty with their customers.

High-quality materials also play a pivotal role in shaping brand perception. A well-crafted bag made from reliable fabric conveys professionalism and attention to detail. It’s not just about aesthetics; it's about performance. The right fabric enhances usability, increases product lifespan, and reduces the need for frequent replacements—aligning with global trends toward sustainability and conscious consumption.

Understanding the 0.75 Thickness × 290T Twill × Composite Advantage

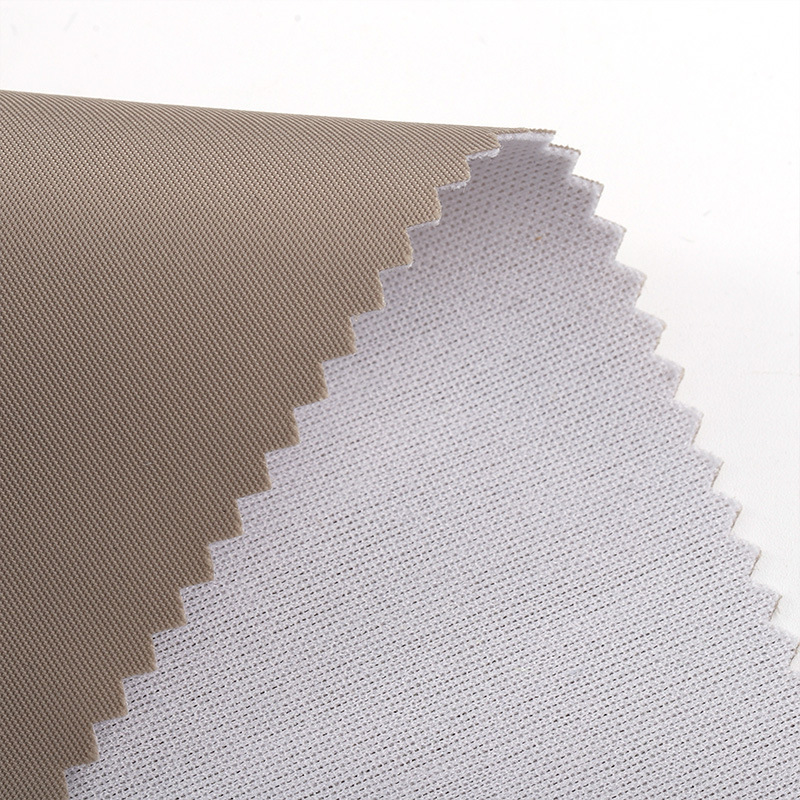

The unique combination of thickness, weave, and composite technology sets this fabric apart from conventional materials. At 0.75mm in thickness, it strikes a perfect balance between flexibility and resilience. Too thin, and the fabric might feel flimsy; too thick, and it could be cumbersome. This optimal thickness ensures that bags remain lightweight yet robust enough to withstand daily wear and tear.

The 290T twill weave adds another layer of sophistication. Twill fabrics are known for their diagonal rib patterns, which enhance both visual appeal and structural integrity. This weave provides a dense yet breathable surface, offering a tactile experience that’s both soft and rugged—ideal for a wide range of bag designs, from minimalist urban styles to rugged outdoor packs.

What truly elevates this fabric is its composite construction. A specialized waterproof membrane is bonded to the base fabric using advanced lamination techniques, ensuring that water resistance is built into the core of the material rather than just being a surface treatment. This method results in long-lasting protection against rain, spills, and humidity, making it a preferred choice for brands focused on all-weather performance.

From Mountains to Metro: Versatility in Every Fiber

One of the most compelling aspects of this fabric is its adaptability across a wide range of use cases. Backpack manufacturers are constantly challenged to meet the diverse needs of travelers, hikers, students, and urban commuters. This fabric rises to the occasion by offering a versatile platform that can be tailored to various bag types and functions.

Whether it's a hiking backpack braving a downpour or a commuter bag enduring daily subway chaos, this material delivers consistent performance. Its ability to maintain shape and integrity under harsh conditions makes it ideal for outdoor enthusiasts and city dwellers alike. Moreover, the fabric’s resistance to mildew and UV degradation ensures that bags stay fresh-looking over time, even with prolonged exposure to the elements.

Why This Fabric is a Smart Choice for Mass Production

For manufacturers looking to scale, consistency and reliability are crucial. This fabric is designed for high-volume production without compromising on quality. Its uniform texture and thickness ensure minimal variation between batches, which is essential for maintaining brand standards across large product lines.

Cost efficiency is another major advantage. While high-performance materials often come with a premium price tag, this fabric offers a compelling balance between cost and value. It allows brands to maintain competitive pricing while delivering a product that exceeds customer expectations. Additionally, its compatibility with a wide range of bag designs—from duffels to laptop sleeves—means it can be used across multiple product categories, streamlining procurement and reducing complexity in production workflows.

Aligning with Sustainability Trends

As environmental awareness grows, brands are under increasing pressure to adopt eco-conscious practices. This fabric supports sustainable manufacturing through its reduced reliance on chemical coatings. The high-density weave naturally limits water penetration, minimizing the need for heavy waterproofing treatments that can be harmful to the environment.

Furthermore, the fabric is often produced using low-impact dyes and energy-efficient processes, aligning with green supply chain initiatives. For brands committed to reducing their carbon footprint, this material represents a smart, forward-thinking choice that supports both business goals and environmental responsibility.

How to Choose the Right Fabric for Your Product

Selecting the ideal fabric involves more than just checking specifications. It requires a deep understanding of real-world performance. Key metrics such as tensile strength, water column rating, and breathability should all be considered. But equally important is hands-on testing—evaluating how the fabric behaves under stress, how it drapes, and how it responds to repeated use.

Designers, engineers, and procurement teams must collaborate closely to ensure that the fabric meets both aesthetic and functional requirements. A material might look impressive on paper, but only through rigorous testing can its true suitability be confirmed. This holistic approach helps prevent costly mistakes and ensures that the final product delivers on every promise.

Why This Fabric is Becoming the Industry Standard

Leading manufacturers are increasingly adopting this fabric due to its proven track record in both performance and production. Compared to traditional materials like nylon or Oxford fabric, it offers superior water resistance without sacrificing comfort or flexibility. Its high-density structure also means that it can often do without additional coatings, which can degrade over time and contribute to environmental waste.

Feedback from industry professionals highlights its ease of use during cutting and sewing, as well as its ability to maintain a clean finish even after repeated washing and exposure. As the demand for multifunctional, eco-friendly products continues to rise, this fabric is well-positioned to become a staple in the bag manufacturing world.