Premium 0.75 Thickness 290T Twill Composite Bag Fabric – Durable & Waterproof Polyester for Wholesale

When it comes to sourcing high-quality materials for bag manufacturing, the choice of fabric can make or break a product’s success in the market. The 0.75 thickness 290T twill composite bag fabric has rapidly gained traction among leading manufacturers, especially those producing outdoor gear, travel bags, and premium backpacks. But what exactly makes this fabric stand out in a sea of options? Let’s take a closer look at its features, benefits, and why it’s quickly becoming the go-to choice for brands seeking durability, aesthetics, and performance.

Why Leading Bag Manufacturers Are Choosing This Fabric

The rise of the 290T twill composite fabric isn’t just a passing trend—it’s a response to the evolving demands of modern consumers. As outdoor activities gain popularity and urban lifestyles demand versatile, long-lasting products, manufacturers are under pressure to deliver bags that can withstand harsh conditions without compromising on style. This 0.75mm thick fabric combines high-density weaving with a composite waterproof layer, making it ideal for everything from weekend hiking packs to professional duffels.

What sets this fabric apart is its balanced construction. Unlike heavier materials that can feel cumbersome or thinner ones that wear out quickly, this twill weave offers a perfect middle ground. It’s rugged enough to protect against abrasion and weather exposure, yet soft enough to maintain a premium hand feel. Whether you're crafting travel luggage, school backpacks, or tactical gear, this fabric delivers both structural integrity and comfort in use.

The Unique Features Behind Its Performance

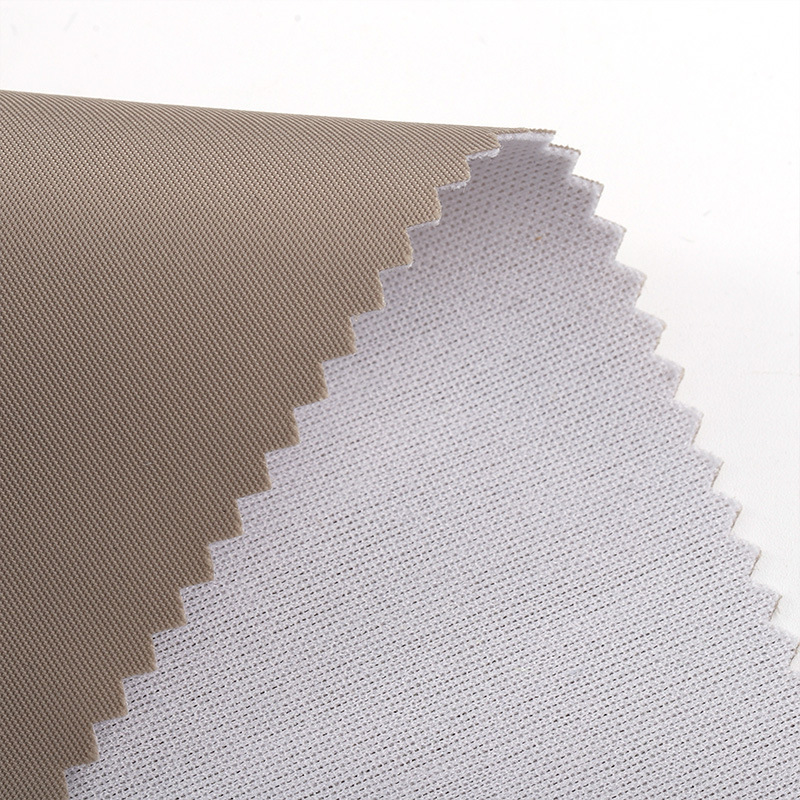

At the core of this fabric’s performance is its advanced construction. The 290T twill weave refers to the thread count per inch—indicating a tightly woven structure that enhances durability. Combined with a high-density polyester base and a lamination process that adds a waterproof barrier, the result is a material that resists water penetration, tearing, and general wear and tear.

One of the most impressive aspects of this fabric is its versatility. Unlike traditional nylon or canvas materials that may require additional coatings or treatments, the 0.75mm thickness ensures the fabric is naturally sturdy while maintaining flexibility. This allows for easy sewing and shaping during the production process, making it highly compatible with a wide range of bag designs and manufacturing techniques.

More Than Just Waterproof – Enhancing Your Product’s Value

Water resistance is just one of the many benefits this fabric brings to the table. Its multi-layered structure also enhances resistance to abrasion, UV degradation, and stains. This means that whether a bag is being dragged across rough terrain or exposed to city rain, it remains in excellent condition over time. For brands aiming to build a reputation for quality and longevity, this is a critical advantage.

Moreover, the material’s adaptability allows it to be used across a wide spectrum of bag types—from lightweight school backpacks to heavy-duty camping gear. Its neutral texture and subtle sheen also make it a designer-friendly option, capable of supporting both minimalist and rugged aesthetics. With consistent color retention and minimal pilling, it ensures that your product maintains its visual appeal through years of use.

Why Wholesale Buyers Love It

From a procurement standpoint, this 290T twill composite fabric offers a compelling combination of cost-efficiency and performance. It strikes the perfect balance between affordability and premium quality, making it an ideal option for large-scale production runs. Its consistent thickness and uniform texture reduce production waste and increase yield rates, which is especially valuable for manufacturers working on tight margins.

Additionally, the fabric’s compatibility with standard industrial sewing machines and lamination techniques makes it easy to integrate into existing production lines. Many well-known brands have already adopted this material in their product lines, citing its reliability and ease of sourcing as key reasons for their continued loyalty.

Aligning with Sustainable Trends

As the global market shifts toward eco-conscious practices, the sustainability of materials is becoming a decisive factor in purchasing decisions. While the 0.75mm 290T twill composite fabric is primarily made from polyester, advancements in textile recycling and eco-lamination processes are making it increasingly possible to produce this fabric using environmentally responsible methods. For brands committed to reducing their carbon footprint, sourcing from suppliers who implement green manufacturing practices can help align product development with broader sustainability goals.

By choosing materials that support recyclability and reduced chemical use, companies can not only meet current environmental standards but also appeal to the growing segment of eco-aware consumers. This fabric’s durability also contributes to sustainability by reducing the need for frequent replacements, thereby extending product lifecycles.

What to Look for in a High-Performance Bag Fabric

When evaluating bag materials for long-term procurement, there are several key criteria to consider: thickness consistency, waterproof rating, tensile strength, colorfastness, and overall tactile quality. The 0.75mm 290T twill composite fabric scores highly across all these metrics. Its precise thickness ensures even wear distribution, while its high thread count provides excellent resistance to tearing and puncturing.

Furthermore, the twill weave pattern itself adds a level of sophistication to the final product. Unlike plain weaves that can appear flat or dull, twill patterns have a subtle diagonal texture that enhances visual depth and luxury perception—making it a preferred choice for upscale brands looking to elevate their product lineups.

Shaping the Future of Bag Design

As consumer preferences evolve and product differentiation becomes more crucial, the role of high-quality materials in shaping design direction is more significant than ever. The 290T twill composite fabric not only supports functional excellence but also opens the door for innovative aesthetics and structural creativity. Whether it’s used in sleek urban totes or rugged expedition backpacks, this fabric allows designers to push boundaries without compromising on durability or practicality.

Looking ahead, it’s not hard to imagine this fabric becoming a staple in the industry. Its blend of performance, adaptability, and visual appeal positions it as a strong candidate for becoming the standard in high-end bag manufacturing. As more brands recognize its value, the demand for this fabric is likely to grow, reinforcing its place in the future of bag design and production.