Premium 0.75 Thickness 290T Twill Composite Bag Cloth – Waterproof & Durable Fabric for Bags

In today's fast-paced world, the demand for high-performance materials in bag manufacturing has never been higher. Consumers are not only looking for style and aesthetics but also durability, water resistance, and environmental responsibility. That’s where the Premium 0.75 Thickness 290T Twill Composite Bag Cloth comes into play – a next-generation fabric engineered to meet modern needs while elevating your brand’s value.

Why Your Bag Deserves Superior Fabric

Imagine a backpack that remains unscathed after a sudden downpour, a travel tote that withstands the rigors of airport handling, or a student’s book bag that resists daily wear and tear. These are not just fantasies—they’re realities made possible by high-performance materials like the 290T twill composite fabric. As market trends evolve, consumers increasingly prioritize durability, lightweight design, and eco-conscious materials. Brands that adapt to these demands stand out in a competitive landscape.

Understanding the 290T Twill Advantage

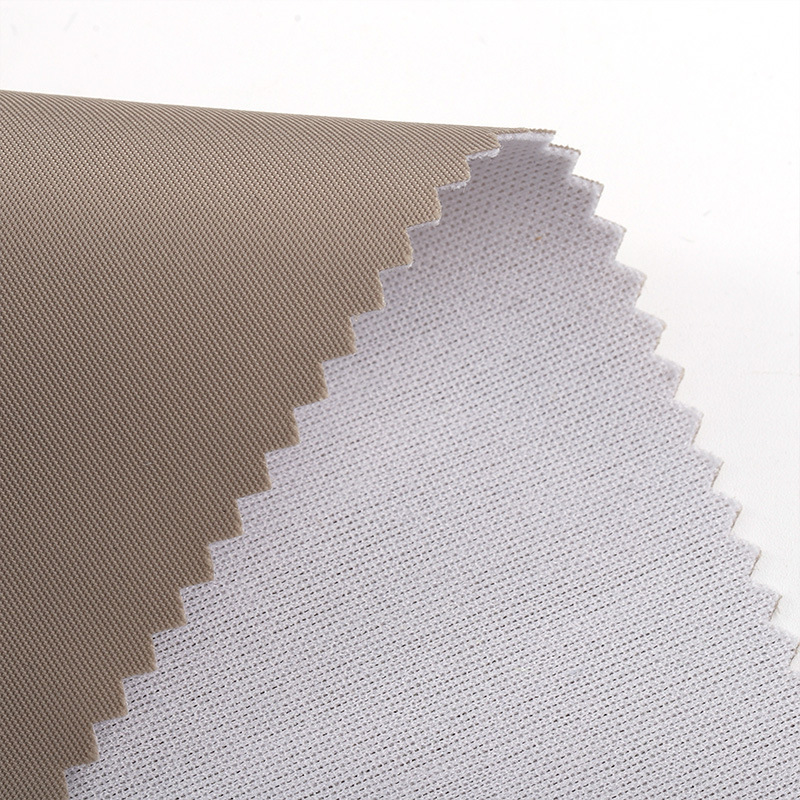

The "290T" designation refers to the tight weave of the fabric, with approximately 290 threads per square inch. This density ensures a tightly woven structure that resists tearing and abrasion while maintaining a soft hand feel. The 0.75mm thickness is the result of careful engineering—thick enough to offer structural integrity and resilience, yet light enough to keep bags portable and easy to carry.

What truly sets this fabric apart is its composite structure. A waterproof membrane is bonded between layers, creating a barrier that repels water without compromising breathability. This means your bags stay dry, contents remain protected, and maintenance becomes effortless.

From Backpacks to Totes – Real-World Applications

Whether you're designing rugged outdoor gear or sleek urban accessories, the versatility of this fabric makes it ideal for a wide array of applications. Outdoor enthusiasts will appreciate its weather resistance in hiking packs. Business travelers benefit from its professional look and resilience in executive bags. Students rely on its wear resistance and easy-cleaning properties in school bags. Even fashion-forward shoppers are drawn to its adaptability in trendy handbags and reusable shopping totes.

Outperforming the Competition

When compared to traditional materials like standard nylon or basic polyester, the 290T twill composite fabric clearly stands out. Its high thread count and composite structure provide superior strength and water resistance. Unlike typical polyester, which can become stiff and prone to water seepage, this fabric remains flexible and fully waterproof. And while nylon may offer durability, it often lacks the refined texture and environmental credentials that this fabric delivers.

From a cost-benefit standpoint, investing in this high-quality fabric translates into long-term savings. Products made from durable materials are less likely to be returned or replaced, and they foster customer loyalty through reliability and performance.

Choosing the Right Supplier Matters

Not all fabrics are created equal, and not every supplier can guarantee consistency in quality. When sourcing materials like this twill composite, it’s essential to partner with a reputable factory that maintains strict quality control. Look for suppliers who provide sample testing, transparent production processes, and reliable batch-to-batch consistency. Strong communication, rigorous inspection, and long-term collaboration are key to ensuring your products meet the highest standards.

The Future of Bag Design Starts Here

As sustainability becomes a driving force in fashion and product design, materials like the 290T twill composite are leading the way. Innovations in fabric technology are pushing the boundaries of what’s possible—recyclable components, customizable textures, and even smart textiles that respond to environmental conditions. Designers are no longer limited by material constraints. Instead, they can create bold, functional, and eco-friendly products that resonate with conscious consumers.

Designers Speak Out

Leading designers in the bag industry have embraced this fabric for its blend of aesthetics and performance. One brand reported a 30% increase in customer satisfaction after switching to this material, citing improved durability and a cleaner appearance over time. Whether crafting minimalist totes or adventure-ready duffels, the fabric’s adaptability allows for creative freedom without sacrificing quality.

If you're ready to elevate your bag designs and deliver a product that stands the test of time, the Premium 0.75 Thickness 290T Twill Composite Bag Cloth is your answer. It’s more than just a fabric—it’s a foundation for innovation, durability, and lasting customer trust.