In today’s world of evolving consumer demands and diverse usage scenarios, the choice of fabric for bag manufacturing has never been more crucial. Whether it’s for travel, outdoor adventures, or daily commuting, a high-performance fabric can make all the difference. This is where our premium 0.75 thickness 290T twill composite cloth comes into play — a versatile, durable, and waterproof solution for modern bag production.

Why Modern Bag Manufacturing Needs High-Performance Fabrics

As lifestyles become more dynamic, so do the expectations for everyday carry products. Consumers no longer settle for aesthetics alone; they demand functionality, resilience, and adaptability. Whether it’s a backpack for a hiking trail, a laptop bag for the daily commute, or a weekend travel duffel, the fabric must endure wear, weather, and weight. That’s why manufacturers are increasingly turning to advanced composite materials that blend strength with flexibility — and none do it better than our 290T twill composite fabric.

Understanding 290T Twill Composite Cloth

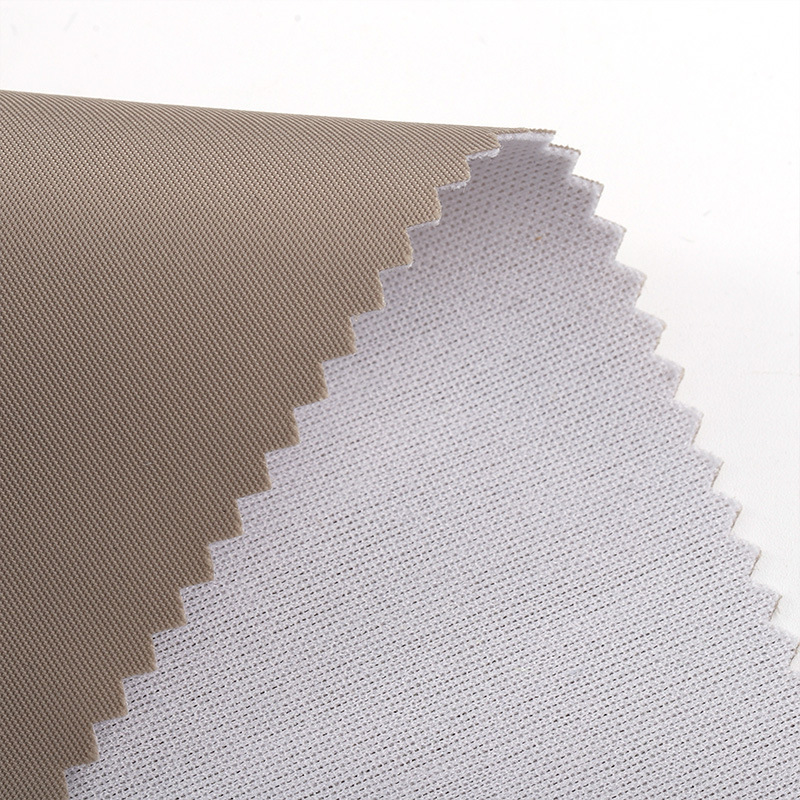

The term “290T” refers to the thread count per square inch, indicating a tightly woven structure that significantly enhances durability. This density not only boosts strength but also ensures a smoother, more refined finish. When combined with the twill weave — known for its diagonal rib pattern — the result is a fabric that feels premium to the touch and offers superior resistance to abrasion and wrinkling.

At 0.75mm thickness, this fabric strikes the perfect balance between ruggedness and flexibility. The composite layering technique ensures a strong bond between the woven polyester and the waterproof membrane, making it ideal for environments where moisture resistance is non-negotiable. This construction also enhances dimensional stability, making it easier to cut and sew during large-scale production.

Three Core Advantages of This Fabric

One of the standout features of this material is its exceptional waterproof capability. Thanks to a high-quality lamination process, the fabric can withstand heavy rain and humid conditions without compromising its structural integrity. This makes it an excellent choice for outdoor gear and travel accessories.

Beyond its waterproofing, the fabric also exhibits remarkable durability. Its high tensile strength ensures that bags made from this material can handle heavy loads without tearing or fraying. This makes it suitable for a wide range of applications — from rugged hiking backpacks to sleek business totes.

Despite its strength, the fabric remains surprisingly lightweight. This feature is essential for users who value portability and comfort, especially for students, travelers, and professionals. The soft hand feel and ease of stitching also make it a favorite among manufacturers looking to streamline production without sacrificing quality.

Why Choose This Fabric for Bulk Production?

For manufacturers, sourcing the right fabric involves a careful balance of cost, quality, and scalability. Our 0.75mm 290T twill composite cloth delivers on all fronts. It’s engineered to provide premium performance without inflating production costs, making it a cost-effective solution for large-scale orders.

The fabric’s excellent dyeing properties allow for a wide spectrum of color options, enabling brands to create unique, on-trend collections. Whether you're producing school backpacks, branded promotional totes, or luxury travel luggage, this fabric adapts beautifully to different design needs.

Moreover, our supply chain ensures consistent availability and quick turnaround times, making it ideal for OEM and private-label projects. With stable inventory levels and global shipping capabilities, we help you meet deadlines and exceed customer expectations every time.

Real-World Applications of This Versatile Fabric

From rugged outdoor gear to sleek urban accessories, this fabric has proven itself in a variety of product categories. For example, outdoor enthusiasts rely on backpacks made from this material to protect their gear in unpredictable weather. Its ability to maintain shape and strength under pressure makes it the go-to choice for extreme conditions.

Similarly, students benefit from lightweight, water-resistant school bags that endure daily use without showing signs of wear. Parents appreciate the long-lasting quality, while kids love the modern look and feel.

Even in the luxury market, this fabric is gaining traction. Its use in the outer shell of premium travel luggage enhances both aesthetics and protection, offering a refined yet functional finish that appeals to discerning travelers.

Looking Ahead: The Future of Bag Fabric Innovation

As consumer preferences evolve, so too does the demand for smarter, more sustainable materials. While the future may lean toward eco-friendly alternatives, there’s still a critical need for high-performance fabrics that offer immediate value. Our 0.75 thickness 290T twill composite cloth bridges this gap — providing the durability, functionality, and versatility that brands and consumers alike require today.

For fabric manufacturers and bag producers, staying ahead of the curve means investing in materials that not only meet current standards but also pave the way for future innovation. By choosing this fabric, you're not just investing in a product — you're investing in a foundation for growth, adaptability, and long-term success.