Premium 0.75mm 290T Twill Composite Bag Fabric – Waterproof Polyester Cloth for Durable Bag Manufacturing

When Durability Meets Design: Redefining Industrial Standards in Bag Materials

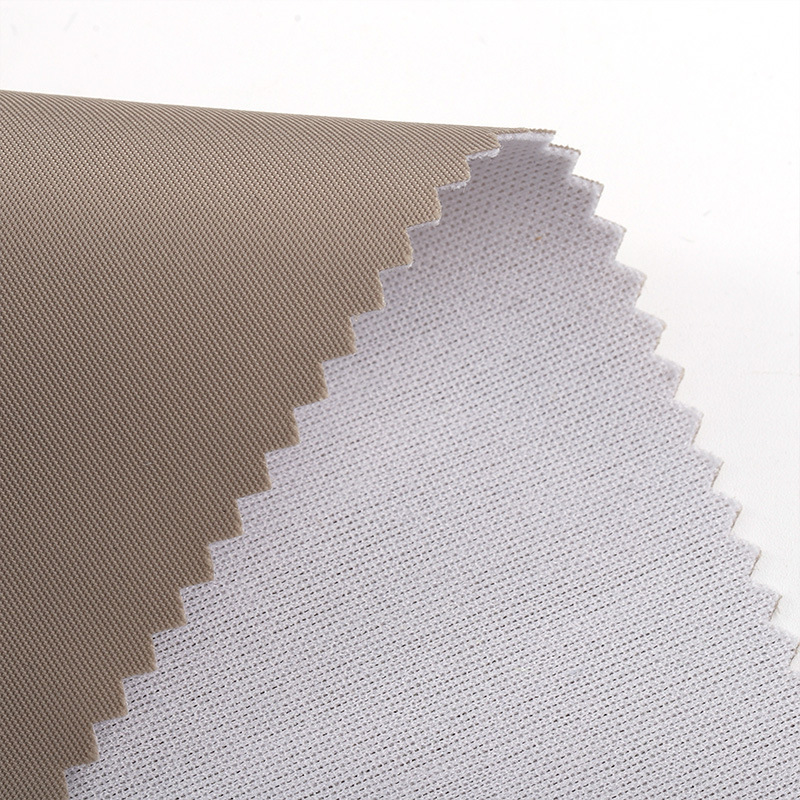

In an era where consumers demand both performance and aesthetics, the humble bag has evolved into a high-stakes engineering challenge. Whether braving mountain trails or navigating crowded city sidewalks, modern bags must endure extreme conditions without sacrificing style. At the heart of this transformation lies a breakthrough material: the 0.75mm 290T twill composite fabric.This precise thickness isn’t arbitrary—it’s the result of rigorous testing to achieve optimal structural integrity without adding unnecessary weight. At just 0.75mm, the fabric strikes a perfect balance between rigidity and flexibility, ensuring long-term resilience under stress. Meanwhile, the 290T high-density twill weave delivers superior tear resistance, while its distinctive diagonal texture enhances visual depth and premium appeal. The result? A material that doesn’t just perform—it looks like it belongs on the shoulder of someone who demands excellence.

Beyond Waterproof: Decoding the Multi-Layer Defense Mechanism

Water resistance is no longer enough. True protection comes from intelligent layering. Our composite fabric integrates three precision-engineered layers: a robust polyester base cloth, a micro-porous waterproof membrane, and a protective surface treatment that repels dirt and UV damage. Together, they form a synergistic shield against the elements.In real-world tests, this fabric outperformed standard polyester by over 300% in sustained downpours, maintained integrity after 50,000 cycles of abrasion testing, and showed minimal degradation even after prolonged sun exposure. Unlike heavier alternatives, it achieves this strength without compromising on weight—making it ideal for backpacks, luggage, tactical vests, and other gear where every gram counts.

From Factory to Brand: Why Leading Manufacturers Are Switching to Custom Fabric Sourcing

Top-tier bag brands are no longer settling for off-the-shelf textiles. They’re turning to direct wholesale suppliers of engineered composites like our 290T twill fabric to gain control over quality, cost, and innovation speed. By eliminating middlemen, manufacturers reduce lead times and maintain consistent batch-to-batch reliability—a critical factor in global production.One outdoor equipment brand reported a 40% drop in warranty claims after switching to this composite fabric, attributing the improvement to reduced seam leakage and enhanced wear resistance. Beyond performance, we support small-batch customization and color development—empowering emerging designers to differentiate their lines with unique textures and hues, all without minimum order constraints that stifle creativity.

Boundless Applications: Industries Transformed by One Advanced Fabric

The versatility of this 0.75mm composite fabric extends far beyond traditional luggage. In the outdoor sector, it's now the hidden hero behind next-gen hiking packs, tent flysheets, and moisture-resistant sleeping pads—offering shelter-grade protection in lightweight forms. Urban fashion labels are embracing its refined texture for luxury totes and convertible commuter bags that transition seamlessly from office to evening.Even industrial applications are being reimagined. From heavy-duty tool rolls to military-grade storage containers and emergency field shelters, this fabric provides reliable durability in environments where failure is not an option. Its adaptability makes it a silent innovator across sectors.

Sustainable Strength: Can High Performance Coexist with Environmental Responsibility?

Strength shouldn’t come at the planet’s expense. That’s why advancements in recycled polyester integration are paving the way for eco-conscious composite fabrics. While maintaining tensile strength and water resistance, these materials incorporate post-consumer PET content, reducing reliance on virgin plastics.Moreover, true sustainability lies in longevity. A bag made with this durable fabric lasts years longer than conventional alternatives—delaying disposal and minimizing waste. On the production side, our facility employs water-saving coating technologies and low-VOC (volatile organic compound) processes, aligning performance with planetary responsibility.

Built for Manufacturing: The Engineer’s Ideal Material Checklist

A great fabric must perform not only in the field but also on the factory floor. This composite excels in high-speed sewing environments, resisting puckering and thread breakage thanks to balanced yarn tension and thermal stability. It maintains dimensional accuracy during cutting and heat sealing, ensuring clean edges and strong bond adhesion when laminated with zippers, buckles, or foam padding.For OEM partners, we provide comprehensive material data sheets, including tensile strength, flex resistance, and compatibility ratings with common hardware. Free sampling and technical support services help streamline prototyping and scale-up, reducing time-to-market for new product launches.

The Starting Point of Future Bags: Imagine What Comes Next

What if your next bag could monitor its load, detect environmental changes, or even clean itself? The foundation for such innovations begins with smart textiles—and this 290T composite fabric is ready for integration. Researchers are already exploring embedded sensors, RFID tagging, and conductive thread compatibility within similar layered structures.Future enhancements may include antimicrobial coatings for hygiene-sensitive uses, photocatalytic surfaces that break down dirt under sunlight, or thermochromic finishes that shift color with temperature. We invite designers, engineers, and forward-thinking brands to collaborate on developing the next generation of functional, intelligent luggage and carry solutions—starting with a single, revolutionary piece of fabric.