Imagine hiking through a sudden mountain storm, your backpack slung tight against the wind, yet inside—your laptop, journal, and spare clothes remain perfectly dry. This isn’t luck; it’s engineering. Behind that confidence lies a quiet revolution in textile innovation: the rise of high-performance, wholesale waterproof bag fabric engineered for real-world resilience. At the heart of this transformation is a material redefining durability and versatility—0.75mm 290T twill composite polyester cloth.

When Raindrops Roll Like Pearls – The Silent Science Behind Dry Gear

Outdoor enthusiasts don’t just want protection—they demand reliability. Whether it’s a downpour on a city commute or weeks trekking through tropical humidity, moisture is the silent enemy of gear longevity. That’s where 0.75mm thick waterproof fabric steps in. Its precisely calibrated coating ensures water beads up and rolls off like mercury on glass, preserving contents even under prolonged exposure. Unlike cheaper laminates that crack or delaminate, this composite structure maintains integrity across temperature extremes and mechanical stress, making it ideal for bags that face the elements daily.

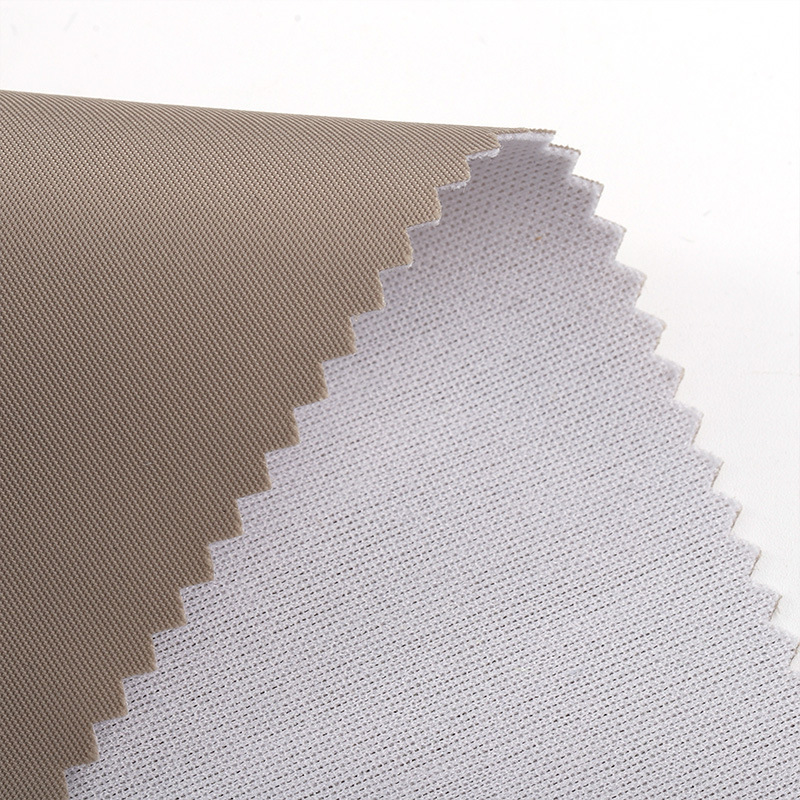

The Strength Woven In: Engineering Elegance with 290T Twill Weave

Beneath the surface, a battle of strength unfolds—one fought between threads. The “290T” designation refers to thread count per inch, a hallmark of density and resilience. Paired with a classic twill weave, this fabric achieves a diagonal ribbing pattern that not only enhances visual depth but also distributes tension more evenly across the material. The result? Superior resistance to tearing, abrasion, and punctures. It drapes smoothly yet stands firm under load—perfect for backpacks, duffels, and tactical gear that endure constant friction and strain.

More Than Just Water Resistance – A Holistic Shield

True performance goes beyond repelling rain. This composite polyester cloth integrates UV inhibitors to resist sun degradation, ensuring colors stay vibrant and fibers don’t weaken after months of exposure. It’s inherently lightweight—reducing overall product weight without sacrificing protection—and resists mold, mildew, and microbial growth, crucial for gear stored in damp environments. From desert trails to coastal kayaking routes, it performs consistently, season after season.

The Manufacturer’s Secret Weapon – Why Wholesalers Choose This Fabric

In mass production, consistency is king. Batch-to-batch uniformity in thickness, tensile strength, and coating adhesion makes this fabric a favorite among OEMs and private-label brands. It cuts cleanly with minimal fraying, sews smoothly on industrial machines, and holds stitching integrity under stress. High color retention allows for bold branding and digital printing, enabling manufacturers to deliver visually striking products without compromising function. For supply chains focused on efficiency and quality control, this material is a cornerstone.

Born for Adventure – Applications That Redefine Utility

This fabric doesn’t just make better backpacks—it enables entirely new categories. Think foldable travel dry bags that compress into pockets, military-grade rucksacks with ballistic-level durability, or child-safe waterproof schoolbags with non-toxic coatings. Cyclists rely on it for mud-resistant panniers; pet owners use it for washable dog carriers. Even outdoor furniture covers and pop-up canopy linings benefit from its blend of flexibility and toughness. Wherever water, wear, or weather threaten function, this fabric rises to the challenge.

The Goldilocks Zone of Thickness – Why 0.75mm Is Just Right

Thinner fabrics may save grams but sacrifice puncture resistance; thicker ones add unnecessary bulk and stiffness. At 0.75mm, this material strikes the ideal balance—robust enough to withstand rugged use, yet flexible enough for ergonomic shaping and compact folding. It supports structured bags without board inserts while remaining pliable for soft-sided designs. This sweet spot maximizes performance across diverse applications, especially those requiring frequent packing and unpacking.

The Green Thread: Sustainability in Modern Polyester Fabrics

As eco-consciousness grows, so does demand for responsible materials. While traditional polyester stems from petroleum, advancements now allow integration of recycled PET (rPET) without compromising waterproof integrity. Combined with PFC-free durable water repellent (DWR) coatings, this fabric can meet strict environmental standards—ideal for brands aiming for bluesign® or OEKO-TEX® certification. Choosing sustainable sourcing today helps build future-proof product lines aligned with global ESG goals.

Design Without Limits – Customization at Your Fingertips

One size never fits all in fashion and function. This base fabric welcomes customization: available in variable widths (typically 58–60 inches), multiple color options, and adaptable to special treatments like flame retardancy, anti-static finishes, or embedded reflective strips for night visibility. Digital printing compatibility opens doors for limited editions, brand collaborations, or region-specific patterns—turning raw material into storytelling canvas.

Partner with the Source – The Power of Direct Factory Collaboration

Going straight to the manufacturer eliminates markup layers and unlocks agility. With low minimum order quantities, technical support, and rapid sampling, direct partnerships empower small brands and startups to compete with industry giants. Real-time communication ensures specifications are met exactly, reducing errors and delays. When you source from the origin, you gain not just cost savings—but creative freedom and faster time-to-market.

The Next Stitch Shapes Tomorrow – Rethinking What a Bag Can Be

Innovation starts long before stitching begins. The next breakthrough bag won’t come from a new zipper or strap design alone—it will emerge from the choice of material. By selecting a technically superior, environmentally conscious, and highly adaptable fabric like 0.75mm 290T twill composite polyester, designers and entrepreneurs lay the foundation for products that last longer, perform better, and stand out in crowded markets. The future of carrying isn’t just about transport—it’s about trust. And that trust is woven, one thread at a time.