In an era where functionality meets fashion, one material is quietly revolutionizing how we think about durability in bags: a high-performance 0.75mm 290T waterproof polyester twill composite fabric. No longer just a hidden layer beneath zippers and linings, this advanced textile is emerging as the backbone of next-generation luggage, backpacks, and outdoor gear.

Why This 0.75mm Composite Fabric Is Redefining Bag Durability Standards

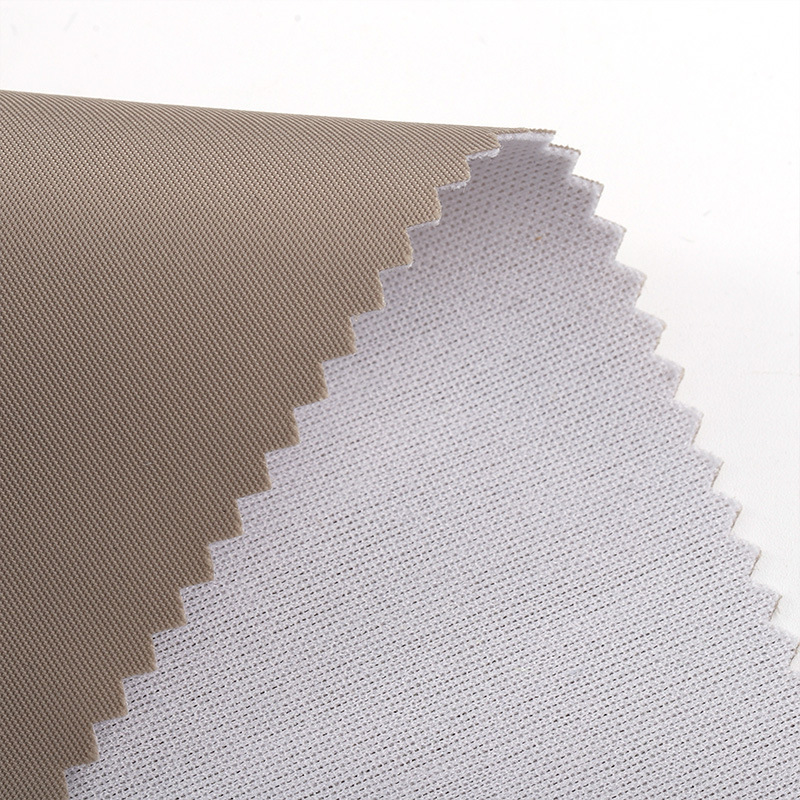

Beneath every well-crafted bag lies what industry insiders call the "invisible hero" — not the zipper, nor the stitching, but the fabric itself. Traditional polyester weaves have long served as the standard, yet they often fall short when faced with abrasion, moisture, or prolonged stress. Enter the 290T twill composite cloth: a meticulously engineered solution that outperforms conventional materials in both resilience and aesthetic appeal.

The key difference? It's not just woven — it's built. By combining tightly interlaced 290-thread-count yarns with a precision-laminated backing, this fabric achieves structural integrity that resists stretching, fraying, and water penetration. Unlike basic ripstop or plain-weave polyesters, which may look sleek at first glance, the 290T twill maintains its form even after years of daily use.

From Factory Floor to Outdoor Adventure: The Journey of a High-Tech Fabric

It all begins with raw polymer pellets, melted and extruded into continuous filament yarns. These are then spun, dyed, and woven using advanced looms capable of maintaining exact tension across thousands of threads per inch. But the real magic happens during the thermal lamination process, where a thin yet robust waterproof membrane is fused under controlled heat and pressure.

The result is a perfectly balanced 0.75mm thickness — substantial enough to provide structure and protection, yet flexible enough for ergonomic shaping. Too thin, and the fabric risks tearing; too thick, and it becomes stiff and heavy. This optimal gauge ensures bags remain lightweight without sacrificing toughness.

The Allure of Twill: Where Strength Meets Sophistication

Look closely, and you’ll notice the distinctive diagonal rib pattern characteristic of twill weaving. More than just visually appealing, this texture enhances surface durability by distributing stress across intersecting yarns. Each thread supports its neighbor, creating a network of micro-reinforcements that resist punctures and abrasions far better than flat weaves.

Touch it, and the smooth, slightly textured finish conveys quality. Designers appreciate how this tactile elegance elevates even minimalist silhouettes, making it ideal for premium urban carry-ons, luxury travel duffels, or technical hiking packs. In fact, many top-tier brands now specify 290T twill precisely because it signals craftsmanship — before a single logo is applied.

Beyond Water Resistance: A Multi-Layered Defense System

True performance goes beyond keeping water out. This composite fabric offers a full suite of protective features: water-repellent coating, stain resistance, and UV protection are all integrated into the fiber matrix. Whether caught in a sudden downpour, brushed against muddy trailside rocks, or left under harsh sunlight, bags made from this material retain their integrity and appearance.

This versatility makes it equally suited for city commuters navigating rainy subways and adventurers trekking through alpine climates. One fabric, countless applications — from school backpacks to military-grade equipment cases.

The Designer’s Secret Weapon: Unleashing Creative Freedom

What truly sets this fabric apart is its adaptability. Easy to cut, consistent in stretch, and highly compatible with industrial sewing machines, it streamlines production while reducing waste. Moreover, it accepts digital printing, screen printing, and sublimation techniques with stunning clarity, allowing designers to bring bold patterns, logos, or camouflage motifs to life without compromising durability.

Imagine a sleek laptop sleeve with geometric prints, a rugged expedition rucksack in earthy camo, or a pastel-toned tote for seasonal collections — all crafted from the same resilient base material. That’s the power of a fabric designed for both function and expression.

Why Direct-From-Factory Supply Chains Are Changing the Game

When brands source directly from manufacturers specializing in technical textiles, they gain more than cost savings — they unlock agility. Cutting out middlemen reduces lead times, improves communication, and enables custom modifications like color batching, weight adjustments, or eco-coating options. For fast-moving consumer brands, this means faster time-to-market and greater responsiveness to trends.

Consistent inventory availability also means fewer production delays, helping maintain brand reliability. And with growing demand for sustainable practices, direct partnerships allow deeper traceability — knowing exactly where and how your fabric was made.

Sustainability Through Longevity: Durability as an Environmental Statement

In a world shifting toward circular economies, true sustainability isn’t always about biodegradability — sometimes, it’s about lasting longer. Every bag made with this high-durability fabric represents fewer replacements, less waste, and reduced carbon footprint over time. Think of it as slow fashion for functional accessories.

Looking ahead, integrating recycled PET-derived polyester into these composites could further enhance environmental credentials without sacrificing performance — a promising frontier already being explored by forward-thinking mills.

The Future of Bag Materials: Lighter, Smarter, Stronger

As technology advances, so do expectations. The next generation of bag fabrics will likely merge smart functionalities — such as embedded sensors or solar-reactive coatings — with enhanced ecological profiles. Yet, the foundation remains unchanged: a balance between strength, weight, and aesthetics.

The 0.75mm 290T twill composite fabric stands at the forefront of this evolution — a benchmark for what modern performance textiles should deliver. From urban streets to remote mountain trails, it proves that the right material doesn’t just carry belongings; it carries innovation forward.