When the skies open and your backpack bears the brunt of a sudden downpour, it's not just about staying dry — it's about trust. Trust that your gear won’t fail, your belongings won’t soak, and your journey continues uninterrupted. Yet far too many bags fall apart after one rainy season, their seams weakened, their fabric peeling or leaking. The truth? The fate of a bag is often sealed long before it hits the market — at the very moment the fabric is chosen.

When an Inch of Fabric Decides a Bag’s Fate: Redefining Durability Standards

Ordinary polyester may look sleek on the showroom floor, but under real-world stress — moisture, abrasion, UV exposure — it quickly shows its limits. What if there were a smarter alternative? Enter the game-changer: composite fabric technology. No longer reserved for military-grade equipment, this innovation has quietly revolutionized how we think about bag materials.

The 0.75mm 290T twill composite bag fabric isn’t just another waterproof coating slapped onto thin weave. It’s a reimagined foundation — where every thread, layer, and finish contributes to a new benchmark in longevity. This isn’t merely about repelling water; it’s about resisting wear, maintaining structure, and enduring years of use without compromise.

Anatomy of Excellence: Deconstructing the 290T Twill Composite Structure

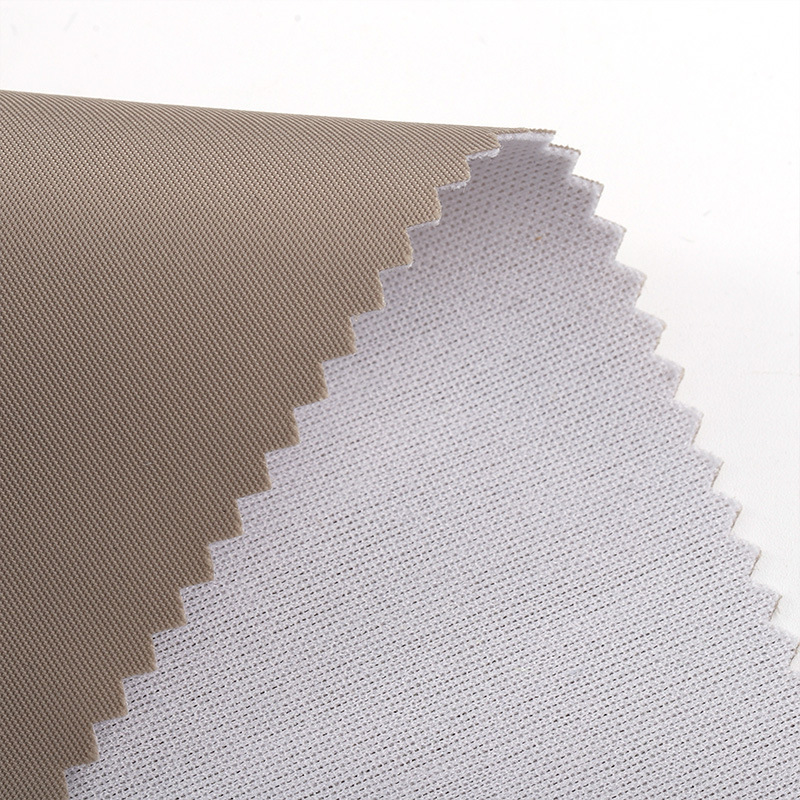

To understand why this fabric stands out, you have to look beneath the surface — literally. Its performance stems from a tri-layered engineering approach that combines strength, protection, and resilience into one seamless textile.

The first layer begins with a tightly woven 290-thread-count polyester twill. Known for its diagonal rib pattern, this weave delivers superior tear resistance while remaining flexible enough for ergonomic bag designs. Unlike plain weaves that crack under tension, the twill structure distributes stress evenly, making it ideal for load-bearing applications like hiking packs or rolling luggage.

Beneath this robust outer shell lies the heart of the innovation: a precision-laminated backing that forms a seamless waterproof barrier. Through advanced composite bonding techniques, the membrane adheres uniformly without bubbling or delamination — common flaws in cheaper laminates. Rain can pool on the surface, yet never penetrate. Even prolonged submersion won’t breach the defense.

Finally, a specialized top treatment elevates functionality further. Treated for UV resistance, stain repellency, and high abrasion tolerance, this fabric maintains its appearance and integrity even after months of daily use. Spills wipe clean. Sunlight doesn’t fade it. And rough handling across concrete floors or rocky trails barely leaves a mark.

In head-to-head tests against standard 600D polyester, our composite fabric demonstrated up to 3x longer lifespan in wet environments and 40% greater resistance to punctures — proving that true durability is built in layers.

More Than a Bag: Building Equipment Meant to Last Generations

This level of performance opens doors across industries. For outdoor enthusiasts, it means confidence during multi-day treks through humid forests or alpine storms. Backpacks made with this fabric keep gear dry, frames intact, and straps secure — no matter the terrain.

Business travelers face different challenges — cramped overhead bins, baggage carousel impacts, and unexpected weather at arrival gates. Luggage and briefcases crafted from this material survive compression, resist scuffs, and shield electronics from spills and damp hotel rooms.

Even fashion brands are embracing performance textiles. As consumers demand “functional aesthetics,” designers are turning to technical fabrics that offer both visual appeal and real-world resilience. From minimalist commuter satchels to edgy streetwear backpacks, the 290T twill composite enables bold silhouettes without sacrificing practicality.

And beyond mainstream uses, niche markets — including tactical gear, photography cases, and industrial tool bags — increasingly rely on these materials for mission-critical reliability.

The Factory Advantage: Full-Chain Quality Control from Fiber to Roll

What separates us from generic suppliers is vertical integration. Our facility manages everything — from raw polymer extrusion to final inspection — ensuring unmatched consistency. Every batch matches in color, thickness, and tensile strength, eliminating production delays due to material variance.

Automated optical scanners detect defects invisible to the human eye, removing flawed sections before shipment. Meanwhile, eco-conscious practices guide our process: low-VOC lamination systems reduce emissions, and we’re actively testing recycled PET blends to support circular economy goals.

A Smart Supply Equation: Balancing Cost, Efficiency & Brand Value

For manufacturers and wholesalers, upgrading fabric pays dividends far beyond upfront cost. Higher material integrity directly correlates with lower return rates and higher customer satisfaction. Imagine fewer complaints about leaking seams or torn straps — just loyal users praising your product’s toughness.

We support agile development with flexible MOQs, allowing brands to test new lines with small trial runs before scaling. Plus, customization options — such as custom dyeing, anti-microbial coatings, or variable widths (from 58” to 64”) — ensure your design vision stays uncompromised.

The Future of Carry: Where Function Meets Innovation

What’s next? We're exploring smart integrations — thermochromic threads that shift hue with temperature, bio-based polyesters derived from sugarcane, and ultra-lightweight variants with reinforced fiber grids. The future of bag materials isn’t just durable — it’s adaptive, sustainable, and intelligent.

As consumer expectations evolve, so must supply chains. Brands that embrace next-gen textiles today aren’t just building better products — they’re shaping the future of mobility.

Ready to collaborate? We invite designers, startups, and established manufacturers to join our material innovation program. Let’s build the next generation of carry — together.