In an era where consumers demand more from their everyday carry—from rugged backpacks to weather-resistant travel luggage—the materials behind these products are undergoing a quiet revolution. At the heart of this transformation lies a single, powerful innovation: 0.75mm 290T waterproof polyester twill composite fabric. This isn’t just another textile—it’s redefining how bags are built, used, and trusted across the globe.

From Backpacks to Luggage: How One Fabric is Reshaping the Bag Industry

The modern consumer no longer settles for flimsy zippers or fabrics that fray after a season of use. Whether it’s a daily commuter tote, a hiking rucksack, or premium cabin luggage, durability and weather resistance have become non-negotiable. This growing expectation has pushed manufacturers to seek advanced materials that balance strength, weight, and cost. Enter our wholesale 0.75mm waterproof polyester composite cloth—a solution engineered precisely for this shift. Its rise in popularity among leading bag brands reflects a broader industry move toward smarter, longer-lasting design.

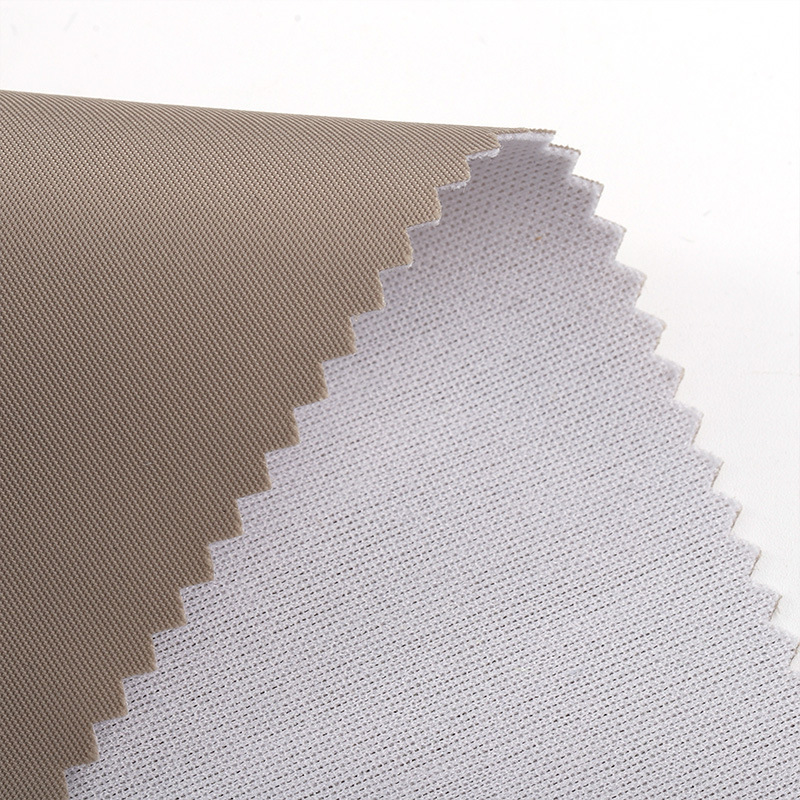

Feel the Difference: Decoding the Science Behind “290T Twill”

What exactly does "290T" mean? Simply put, it refers to a thread count of 290 threads per square inch, woven in a distinctive diagonal pattern known as a twill structure. Unlike plain weaves, which interlace threads at right angles, twill weaving creates a tighter, more resilient fabric with a subtle ribbed texture. This not only enhances visual depth but also significantly improves abrasion resistance and tear strength. In practical terms, your bags won’t just look better—they’ll endure rough sidewalks, packed cargo holds, and years of regular use without showing wear. The 290T density strikes the perfect balance between lightweight performance and industrial-grade toughness.

Waterproof Isn’t Just a Claim—It’s Engineered Into Every Layer

True waterproofing goes beyond surface treatments. Our 0.75mm thickness incorporates a bonded TPU or PVC film layer through precision lamination technology, creating a seamless moisture barrier. When rain hits the fabric, water beads up and rolls off—thanks to controlled surface tension and hydrophobic finishes. We’ve tested this material under simulated monsoon conditions, submersion trials, and prolonged humidity exposure. Results? No seepage, no swelling, no compromise. Whether it's a sudden downpour during a city commute or weeks in a damp basement storage, your product stays dry inside, maintaining trust and functionality.

Factory Direct Advantage: Why Raw Material Quality Shapes Brand Longevity

For manufacturers, consistency is king. A slight variation in fabric width, color batch, or coating thickness can disrupt entire production lines and delay shipments. Sourcing directly from a specialized bag fabric factory ensures uniform roll-to-roll quality, stable pigment dispersion, and precise 150cm+ fabric widths—critical for minimizing waste and maximizing yield. Brands that partner with reliable suppliers gain predictable lead times, lower defect rates, and stronger margins. It’s not just about buying cheap; it’s about investing in supply chain resilience that supports long-term growth.

Beyond Durability: Unlocking New Design Possibilities

This fabric doesn’t just protect—it inspires. Its inherent stiffness provides excellent body, allowing designers to craft structured silhouettes without internal frames or stiffeners. Think sharp-edged briefcases, ergonomic hiking packs with sculpted airflow channels, or foldable bike panniers that hold shape under load. Additionally, its compatibility with digital printing, embossing, and eco-coating processes opens doors for custom branding, limited editions, and signature patterns—all while preserving technical performance.

The Wholesaler’s Edge: Choosing Materials That Win on the Shelf

End buyers may not read spec sheets, but they respond to cues like “water-resistant,” “reinforced stitching,” and “military-grade fabric.” By integrating 0.75mm 290T polyester into your lineup, you tap into a psychological preference for reliability. For budget-conscious brands, this material delivers premium perception at competitive pricing—helping maintain healthy margins without sacrificing quality. And for OEM/ODM clients, customization options abound: choose matte or glossy coatings, adjust thickness slightly based on application, or request recycled yarn variants for eco-focused collections.

Looking Ahead: The Sustainable Evolution of Polyester Fabrics

The future of textiles is green. Innovations in recycled PET-based polyester and bio-derived TPU coatings are already making waves. These eco-conscious alternatives reduce reliance on virgin plastics and lower carbon footprints, all while matching—or exceeding—the mechanical properties of conventional fabrics. Forward-thinking manufacturers are adopting low-impact dyeing techniques and exploring biodegradable lamination layers. As global regulations tighten around sustainability, early adoption of greener materials positions your brand as both responsible and resilient.

The 0.75mm 290T waterproof polyester twill composite isn’t just a component—it’s a competitive advantage. From storm-ready functionality to sleek design versatility and sustainable potential, it empowers creators to build better bags, faster and smarter. For wholesalers and producers alike, aligning with this evolution means staying ahead of trends, meeting customer expectations, and shaping the next generation of carry solutions—one durable fiber at a time.